$49.99

Document Type

Service ManualRegion

WorldWideLanguage

EnglishType of Equipment

Articulated Dump TruckIllustrated factory Service Manual for BELL Articulated Dump Trucks Models B18D 6X4, B18D 6X6, B20D 6X4, B25D 6X6, B25DN 6X6 and B30D 6X6.

This manual will assist you in diagnosing, analyses, testing, and repair for your articulated dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

B18D 6X4 (Mk 7)

B18D 6X6 (Mk 7)

B20D 6X4 (Mk 7)

B25D 6X6 (Mk 7)

B25DN 6X6 (Mk 7)

B30D 6X6 (Mk 7)

Format: PDF, 495 pages

Language: English

Publication Date: 01 Jun 2012

Table of Contents:

SAFETY 17

Specification 17

General 17

Safety Features 17

Material Safety Data Sheet (MSDS) 18

Unauthorised Modifications of ROPS and FOPS 18

Loosening or Removal Of ROPS and FOPS 18

Noise Emission Levels 18

Safety Regulations 19

General Safety 19

TYRE INFORMATION 30

Tyres and Rims 30

Tyre Pressures - General 30

Tyre Pressures - Inflation Pressure, Hot vs. Cold 30

OPERATIONAL CHECK-OUT PROCEDURE 35

Operational Check 35

Ignition Button Pressed ONCE, Engine OFF 35

Ignition Button Pressed (Second Stage), Engine Start 36

Engine Stop Button Pressed 38

ENGINE 39

Engine (OM 906 LA Shown) 39

SCR 44

SCR - Components 44

The Metering device 45

Display Menu Tachometer (B20D Shown) 53

Slow and Fast Idle Adjustment 53

Valve Clearance Adjustment 53

Exhaust Brake Adjustment 54

Oil Pump Pressure Test 60

ELECTRICAL SYSTEM 63

Schematics 63

Electrical Schematic Symbols 63

Electrical Schematics 64

Earth Connections 91

Fuse and Relay Layout 91

ADM-Mercedes ECU Inputs and Outputs 105

a. ELECTRICAL SYSTEM - Connectors 111

Connectors 111

b. Fault Codes & MDU Fault Display 153

Engine Fault Codes (ADM) 153

Engine Fault Codes (PLD-MR) 162

CCU, MDU & OEU Fault Codes 178

c. MDU Menu Structure 193

General Description 239

MDU3 Menu Structure 193

Default Display 196

Accessing Service Mode 198

Main Menu 199

Specifications and Tests 229

TRANSMISSION 239

Planetary Gears Sets 244

Transmission Cross Sectional Diagram 246

Power Flow 247

Functional Description Hydraulic System 248

General Description 254

Speed Sensors 257

Control Module 257

Wiring Harnesses 258

Autodetect Feature 261

Hydraulic Circuits 263

Neutral to Drive Transition 265

st Range Operation 265

st Range to 2nd Range Transition 266

Torque Converter And Lube Pressure Circuits 277

Exhaust Backfill Pressure 277

Definitions And Abbreviations 278

Identification of Potential Circuit Problems 293

Oil Level Sensor (OLS) 284

Diagnostic Code Memory 286

TRANSMISSION ZF 6 HP 592 C PLUS 295

General Descriptions 295

Stall Speeds 299

Stall Speeds (Blu@dvantage) 299

Planetary Gears and Power Flows 300

Hydraulic System 306

Valve Schematic 1 307

Retarder Lever 312

ZF Gear Shift Control 313

Internal Solenoids 315

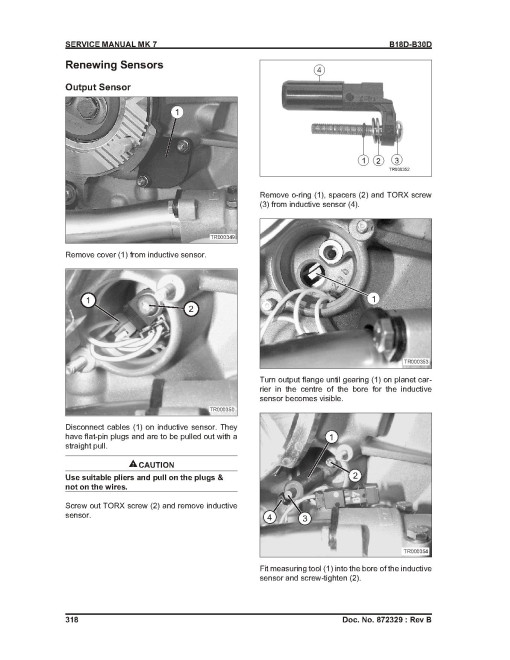

Renewing Sensors 318

External Solenoids 325

Diagnostic Codes 325

Transmission Control Unit Error Codes 334

PNEUMATIC SYSTEM 353

Pneumatic System Schematic 353

Pneumatic System Operation 355

Fault Finding 360

Adjustments and Tests 362

Pneumatic System Main Pressure Test and Adjustment 362

Park Brake Pressure Test 362

Park Brake Adjustment 363

HYDRAULIC SYSTEM 367

Hydraulic System Circuit Symbols 367

Hydraulic Schematic B18D and B20D Without Wet Disc Brakes 368

Hydraulic Schematic B25D and B30D Without Wet Disc Brakes 369

Hydraulic Schematic B30D With Wet Disc Brakes 370

Articulated Dump Truck Hydraulic System Operation 371

Main Hydraulic Pump Operation 373

Main Hydraulic Pump Load Sense Operation 374

Steering Valve Operation 376

Secondary Steering Pump Operation 378

Hydraulic System Manifold (Front View) 381

Hydraulic System Manifold (Rear View) 382

Hydraulic System Manifold (Right View) 383

Manifold Schematic 384

General Description 385

Service Brake System Operation 386

Steering And Secondary Steering System Operation 387

Bin Operation 388

Diagnostic Procedure 391

Tests and Adjustments 400

Digital Thermometer Installation 400

Digital Analogue Pressure/Temperature Analyser Installation 400

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy 401

Hydraulic System Warm-Up Procedure 401

Setting Hydraulic Pressure 402

Activate the Hydraulic Pressure Setup Mode: 403

Calibrate the Bin Position Sensors: 403

Set the Emergency Steering Pump Pressures 403

Set the Emergency Steering Pump Residual Pressure 403

Set the Emergency Steering Pump Compensating Pressure: 404

Set the Main Pump Residual Pressures B18/B30 405

Set the Main Pump Compensating Pressure B18/B30 405

Set the Steering Pressure 407

Set the Brake Circuit Pressures: 407

Accumulator Charge Pressure Check and Re-charge Procedure 409

Set the Bin Tip Pilot Pressure 410

Cycle Time Test 411

HEATING, VENTILATION AND AIR CONDITIONING 413

Air Conditioning System Cycle Of Operation 413

Heater Core Operation 414

Tests 419

Operational Checks 419

R134A Air Conditioning System Test 420

Air Freeze Control Switch Test 422

Air Compressor Clutch Test 422

Air High/Low Pressure Switch Test 422

Air Expansion Valve Test 423

Expansion Valve Bench Test 424

Refrigerant Leak Test 425

SERVICING, SCHEDULES & LUBRICATION CHART 429

Hydraulic System Overview 429

De-pressurising the Hydraulic System 429

Engine Oil 430

Service Schedules - Pg 1 of 2 435

Service Schedules - Pg 2 of 2 436

HOURS SERVICE AND CHECKS 441

Service Instructions 441

HOURS SERVICE AND CHECKS 445

Service Instructions 445

Change Engine Oil And Replace Filter 445

Check Engine Air Intake System 445

Drain the Racor Fuel Filter 445

Check for oil leaks 446

Tilt and lower the cab 446

Loosen Cab Mounting Bolts Front And Rear Left Hand Side 446

Lower The Cab 447

The Transmission Fluid Level 447

Dipstick Check - Transmission Fluid COLD (Cold Check) 447

Dipstick Check - Transmission Fluid HOT (Hot Check) 448

Check Park Brake Pad Wear 449

Check Service Brake Pad Wear 449

Check The Transfer Case Fluid Level 450

Check Front Axle Suspension Struts 450

General Check Drive Line & Suspension Fasteners 451

Transfer Case Breather (Located under the Hydraulic Reservoir) 451

Transmission Breather And Axle Breathers 451

Middle Axle Breather 451

Rear Axle Breather 452

Inspect, Clean And Replace Cab Air Filter 452

Check Batteries, Clean And Tighten Terminals 453

Check Electrical Connectors, Harnesses And Looms 453

Check Work Lights, Reverse Buzzer And Horns 453

Record & Delete Fault Codes On The MDU 453

Check The Operator Controls And Instruments 454

Grease All Grease Points 454

Lubricate Bin Pivots 454

Articulation Joints, Oscillation Tube Through Drive Shaft Bearing Front And Steering Cylinders Rear Pivot Points 454

Oscillation Tube And Oscillation Tube Through Drive Shaft Bearing Rear 454

Grease Tailgate Pivot Points (If Equipped) 455

Check Hydraulic Oil Level 455

Service Brake Accumulator Routine Test 455

Replace Hydraulic Reservoir Breather 455

Grease Prop Shaft Slip Joint 456

Check Bin Shock Pad Clearance 456

Bin Pad Spacing (Field spacing only) 457

Clean Headlights 458

HOURS SERVICE AND CHECKS 459

Service Instructions 459

Adjust Engine Valve Clearance 459

Replace Primary Fuel Filter (Water Separator) 459

Replace Secondary Fuel Filter 459

Replace Crankcase Breather Filter 459

Remove Tappet Cover 459

Remove Tappet Cover 459

Change the Primary Filter Element 460

Check Coolant Condition 461

Check The Fan Belt Condition 461

Replace Hydraulic Oil Return Filter 462

Check Axle Oil Level 463

Check Final Drive Oil Levels 463

HOURS SERVICE AND CHECKS 465

Service Instructions 465

Change the Secondary Filter Element 465

Change Transmission Oil 465

Drain Transmission Oil Cooler 465

Replace Transmission Oil Filters 466

Fill Transmission 466

Change Transfer Case Oil 466

Change Axle Oil 467

Change Final Drive Oil 468

Check Service Brake Disc Thickness 468

Check Front Hubs 468

Replace Pneumatic System Dryer Filter 469

SCR Pump Module Accumulator Test & Pressure 469

HOURS SERVICE AND CHECKS 471

Service Instructions 471

Change jockey pulley bearing (Tensioner Pulley) 471

Remove Idler Pulley Assembly 471

Change Aircon Pulley Assembly 472

Change all axle driveline cross and rollers 472

Replace The Suction Screen 472

HOURS SERVICE AND CHECKS 473

Service Instructions 473

Replace Fan Belt 473

Change Hydraulic Oil 473

Fill Hydraulic Tank 474

Change Pneumatic Block Breather Filters 474

AS REQUIRED SERVICE 475

Introduction 475

Service Instructions 475

Check the Engine Compartment Components 475

Clean/Replace Primer Pump Fuel Screen 476

Prime fuel system 476

Change Engine Coolant 477

Clean Cooling System 478

Check for Oil and Fuel Leaks 478

Clean the Air Cleaner Pre-cleaner Bowls 478

Clean Air Conditioning Filters 478

Grease Hinges 478

Check And Clean Coolers 478

Hydraulic Oil Cleanliness Sampling Procedure 478

MISCELLANEOUS SERVICE AND CHECKS 481

Service Instructions 481

Inspect Serpentine Belt 481

Change Wheels 481

Using Battery Charger 481

Replace Batteries 482

Replace Front Turn Signal Bulb, Headlight Bulb and Front Park Light Bulb 482

Replace Front Turn Signal Bulb 483

Replace Headlight Bulb 483

Replace Front Park Light Bulb 483

Reassemble Headlight Assembly 483

Adjust Headlights 483

Replace Backup Light and Work Light (If Equipped) 484

Replace Tail and Brake Light and Rear Turn Signal Light 484

Replace Dome Light Bulb and Circuit Breaker Compartment Light Bulb 484

STORAGE AND PRESERVATION 485

Introduction 485

General 485

Category 1 - Laid up for up to 12 months 485

Category 2 - Laid up for 12 to 36 months 486

Category 3- Laid up for up more than 36 months 486

TROUBLE SHOOTING 487

This manual will assist you in diagnosing, analyses, testing, and repair for your articulated dump truck.

You can use a Windows, Mac, or Android device to view this manual. You only need to have a PDF reader installed.

Covered Models:

B18D 6X4 (Mk 7)

B18D 6X6 (Mk 7)

B20D 6X4 (Mk 7)

B25D 6X6 (Mk 7)

B25DN 6X6 (Mk 7)

B30D 6X6 (Mk 7)

Format: PDF, 495 pages

Language: English

Publication Date: 01 Jun 2012

Table of Contents:

SAFETY 17

Specification 17

General 17

Safety Features 17

Material Safety Data Sheet (MSDS) 18

Unauthorised Modifications of ROPS and FOPS 18

Loosening or Removal Of ROPS and FOPS 18

Noise Emission Levels 18

Safety Regulations 19

General Safety 19

TYRE INFORMATION 30

Tyres and Rims 30

Tyre Pressures - General 30

Tyre Pressures - Inflation Pressure, Hot vs. Cold 30

OPERATIONAL CHECK-OUT PROCEDURE 35

Operational Check 35

Ignition Button Pressed ONCE, Engine OFF 35

Ignition Button Pressed (Second Stage), Engine Start 36

Engine Stop Button Pressed 38

ENGINE 39

Engine (OM 906 LA Shown) 39

SCR 44

SCR - Components 44

The Metering device 45

Display Menu Tachometer (B20D Shown) 53

Slow and Fast Idle Adjustment 53

Valve Clearance Adjustment 53

Exhaust Brake Adjustment 54

Oil Pump Pressure Test 60

ELECTRICAL SYSTEM 63

Schematics 63

Electrical Schematic Symbols 63

Electrical Schematics 64

Earth Connections 91

Fuse and Relay Layout 91

ADM-Mercedes ECU Inputs and Outputs 105

a. ELECTRICAL SYSTEM - Connectors 111

Connectors 111

b. Fault Codes & MDU Fault Display 153

Engine Fault Codes (ADM) 153

Engine Fault Codes (PLD-MR) 162

CCU, MDU & OEU Fault Codes 178

c. MDU Menu Structure 193

General Description 239

MDU3 Menu Structure 193

Default Display 196

Accessing Service Mode 198

Main Menu 199

Specifications and Tests 229

TRANSMISSION 239

Planetary Gears Sets 244

Transmission Cross Sectional Diagram 246

Power Flow 247

Functional Description Hydraulic System 248

General Description 254

Speed Sensors 257

Control Module 257

Wiring Harnesses 258

Autodetect Feature 261

Hydraulic Circuits 263

Neutral to Drive Transition 265

st Range Operation 265

st Range to 2nd Range Transition 266

Torque Converter And Lube Pressure Circuits 277

Exhaust Backfill Pressure 277

Definitions And Abbreviations 278

Identification of Potential Circuit Problems 293

Oil Level Sensor (OLS) 284

Diagnostic Code Memory 286

TRANSMISSION ZF 6 HP 592 C PLUS 295

General Descriptions 295

Stall Speeds 299

Stall Speeds (Blu@dvantage) 299

Planetary Gears and Power Flows 300

Hydraulic System 306

Valve Schematic 1 307

Retarder Lever 312

ZF Gear Shift Control 313

Internal Solenoids 315

Renewing Sensors 318

External Solenoids 325

Diagnostic Codes 325

Transmission Control Unit Error Codes 334

PNEUMATIC SYSTEM 353

Pneumatic System Schematic 353

Pneumatic System Operation 355

Fault Finding 360

Adjustments and Tests 362

Pneumatic System Main Pressure Test and Adjustment 362

Park Brake Pressure Test 362

Park Brake Adjustment 363

HYDRAULIC SYSTEM 367

Hydraulic System Circuit Symbols 367

Hydraulic Schematic B18D and B20D Without Wet Disc Brakes 368

Hydraulic Schematic B25D and B30D Without Wet Disc Brakes 369

Hydraulic Schematic B30D With Wet Disc Brakes 370

Articulated Dump Truck Hydraulic System Operation 371

Main Hydraulic Pump Operation 373

Main Hydraulic Pump Load Sense Operation 374

Steering Valve Operation 376

Secondary Steering Pump Operation 378

Hydraulic System Manifold (Front View) 381

Hydraulic System Manifold (Rear View) 382

Hydraulic System Manifold (Right View) 383

Manifold Schematic 384

General Description 385

Service Brake System Operation 386

Steering And Secondary Steering System Operation 387

Bin Operation 388

Diagnostic Procedure 391

Tests and Adjustments 400

Digital Thermometer Installation 400

Digital Analogue Pressure/Temperature Analyser Installation 400

Hydraulic Oil Cleanup Procedure Using Portable Filter Caddy 401

Hydraulic System Warm-Up Procedure 401

Setting Hydraulic Pressure 402

Activate the Hydraulic Pressure Setup Mode: 403

Calibrate the Bin Position Sensors: 403

Set the Emergency Steering Pump Pressures 403

Set the Emergency Steering Pump Residual Pressure 403

Set the Emergency Steering Pump Compensating Pressure: 404

Set the Main Pump Residual Pressures B18/B30 405

Set the Main Pump Compensating Pressure B18/B30 405

Set the Steering Pressure 407

Set the Brake Circuit Pressures: 407

Accumulator Charge Pressure Check and Re-charge Procedure 409

Set the Bin Tip Pilot Pressure 410

Cycle Time Test 411

HEATING, VENTILATION AND AIR CONDITIONING 413

Air Conditioning System Cycle Of Operation 413

Heater Core Operation 414

Tests 419

Operational Checks 419

R134A Air Conditioning System Test 420

Air Freeze Control Switch Test 422

Air Compressor Clutch Test 422

Air High/Low Pressure Switch Test 422

Air Expansion Valve Test 423

Expansion Valve Bench Test 424

Refrigerant Leak Test 425

SERVICING, SCHEDULES & LUBRICATION CHART 429

Hydraulic System Overview 429

De-pressurising the Hydraulic System 429

Engine Oil 430

Service Schedules - Pg 1 of 2 435

Service Schedules - Pg 2 of 2 436

HOURS SERVICE AND CHECKS 441

Service Instructions 441

HOURS SERVICE AND CHECKS 445

Service Instructions 445

Change Engine Oil And Replace Filter 445

Check Engine Air Intake System 445

Drain the Racor Fuel Filter 445

Check for oil leaks 446

Tilt and lower the cab 446

Loosen Cab Mounting Bolts Front And Rear Left Hand Side 446

Lower The Cab 447

The Transmission Fluid Level 447

Dipstick Check - Transmission Fluid COLD (Cold Check) 447

Dipstick Check - Transmission Fluid HOT (Hot Check) 448

Check Park Brake Pad Wear 449

Check Service Brake Pad Wear 449

Check The Transfer Case Fluid Level 450

Check Front Axle Suspension Struts 450

General Check Drive Line & Suspension Fasteners 451

Transfer Case Breather (Located under the Hydraulic Reservoir) 451

Transmission Breather And Axle Breathers 451

Middle Axle Breather 451

Rear Axle Breather 452

Inspect, Clean And Replace Cab Air Filter 452

Check Batteries, Clean And Tighten Terminals 453

Check Electrical Connectors, Harnesses And Looms 453

Check Work Lights, Reverse Buzzer And Horns 453

Record & Delete Fault Codes On The MDU 453

Check The Operator Controls And Instruments 454

Grease All Grease Points 454

Lubricate Bin Pivots 454

Articulation Joints, Oscillation Tube Through Drive Shaft Bearing Front And Steering Cylinders Rear Pivot Points 454

Oscillation Tube And Oscillation Tube Through Drive Shaft Bearing Rear 454

Grease Tailgate Pivot Points (If Equipped) 455

Check Hydraulic Oil Level 455

Service Brake Accumulator Routine Test 455

Replace Hydraulic Reservoir Breather 455

Grease Prop Shaft Slip Joint 456

Check Bin Shock Pad Clearance 456

Bin Pad Spacing (Field spacing only) 457

Clean Headlights 458

HOURS SERVICE AND CHECKS 459

Service Instructions 459

Adjust Engine Valve Clearance 459

Replace Primary Fuel Filter (Water Separator) 459

Replace Secondary Fuel Filter 459

Replace Crankcase Breather Filter 459

Remove Tappet Cover 459

Remove Tappet Cover 459

Change the Primary Filter Element 460

Check Coolant Condition 461

Check The Fan Belt Condition 461

Replace Hydraulic Oil Return Filter 462

Check Axle Oil Level 463

Check Final Drive Oil Levels 463

HOURS SERVICE AND CHECKS 465

Service Instructions 465

Change the Secondary Filter Element 465

Change Transmission Oil 465

Drain Transmission Oil Cooler 465

Replace Transmission Oil Filters 466

Fill Transmission 466

Change Transfer Case Oil 466

Change Axle Oil 467

Change Final Drive Oil 468

Check Service Brake Disc Thickness 468

Check Front Hubs 468

Replace Pneumatic System Dryer Filter 469

SCR Pump Module Accumulator Test & Pressure 469

HOURS SERVICE AND CHECKS 471

Service Instructions 471

Change jockey pulley bearing (Tensioner Pulley) 471

Remove Idler Pulley Assembly 471

Change Aircon Pulley Assembly 472

Change all axle driveline cross and rollers 472

Replace The Suction Screen 472

HOURS SERVICE AND CHECKS 473

Service Instructions 473

Replace Fan Belt 473

Change Hydraulic Oil 473

Fill Hydraulic Tank 474

Change Pneumatic Block Breather Filters 474

AS REQUIRED SERVICE 475

Introduction 475

Service Instructions 475

Check the Engine Compartment Components 475

Clean/Replace Primer Pump Fuel Screen 476

Prime fuel system 476

Change Engine Coolant 477

Clean Cooling System 478

Check for Oil and Fuel Leaks 478

Clean the Air Cleaner Pre-cleaner Bowls 478

Clean Air Conditioning Filters 478

Grease Hinges 478

Check And Clean Coolers 478

Hydraulic Oil Cleanliness Sampling Procedure 478

MISCELLANEOUS SERVICE AND CHECKS 481

Service Instructions 481

Inspect Serpentine Belt 481

Change Wheels 481

Using Battery Charger 481

Replace Batteries 482

Replace Front Turn Signal Bulb, Headlight Bulb and Front Park Light Bulb 482

Replace Front Turn Signal Bulb 483

Replace Headlight Bulb 483

Replace Front Park Light Bulb 483

Reassemble Headlight Assembly 483

Adjust Headlights 483

Replace Backup Light and Work Light (If Equipped) 484

Replace Tail and Brake Light and Rear Turn Signal Light 484

Replace Dome Light Bulb and Circuit Breaker Compartment Light Bulb 484

STORAGE AND PRESERVATION 485

Introduction 485

General 485

Category 1 - Laid up for up to 12 months 485

Category 2 - Laid up for 12 to 36 months 486

Category 3- Laid up for up more than 36 months 486

TROUBLE SHOOTING 487

General

Document Type

Service ManualRegion

WorldWideLanguage

EnglishType of Equipment

Articulated Dump TruckReviews: 0

There are no reviews for this product.

Questions: 0

No questions about this product.

Similar Products